Color Coded Cleaning Plans!

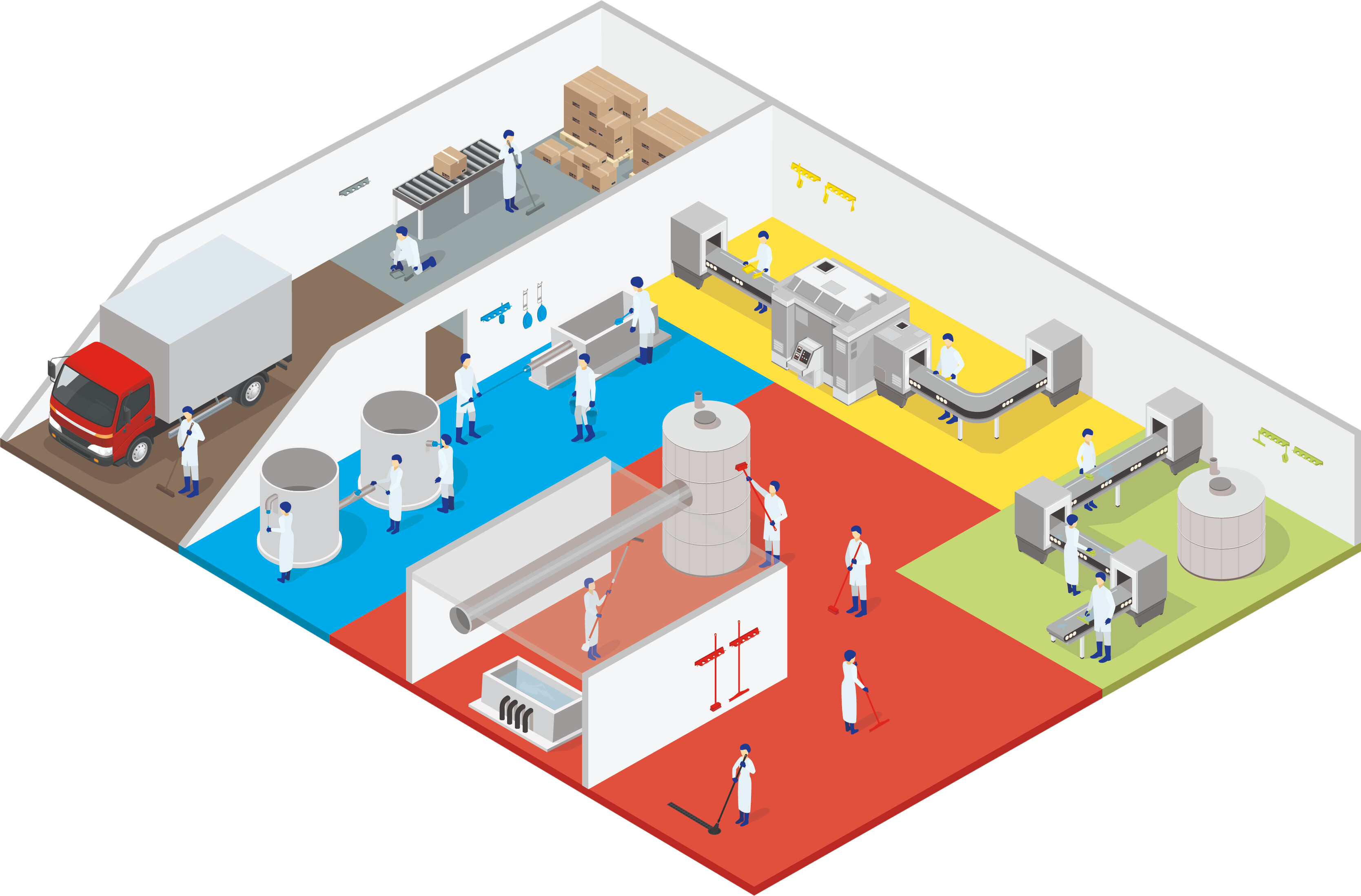

Color-coded tools in the food industry provide visual guidelines for maintaining hygiene and minimizing the risks of foodborne illness and cross-contamination during food processing. There are a variety of different methods for color coding cleaning plans.

Using color-coded tools to separate processes, zones, shifts, or allergens in food production areas minimizes the chance of cross-contamination. As a best practice, tools used in a food processing area should be color-coded based on a risk-based cleaning and sanitation plan.

Get a Free Color-Coded Cleaning Consultation!

Advantages to Color Coded Cleaning:

- Promotes Organization & Cleanliness

- Prevents Cross-Contamination

- Differentiates Areas, Products, Allergens or Shifts

- Hygienic, Neat & Well Organized Cleaning Systems

- Visual Aid for Training

- Preventative Measure for 5S System, HACCP & other regulations.

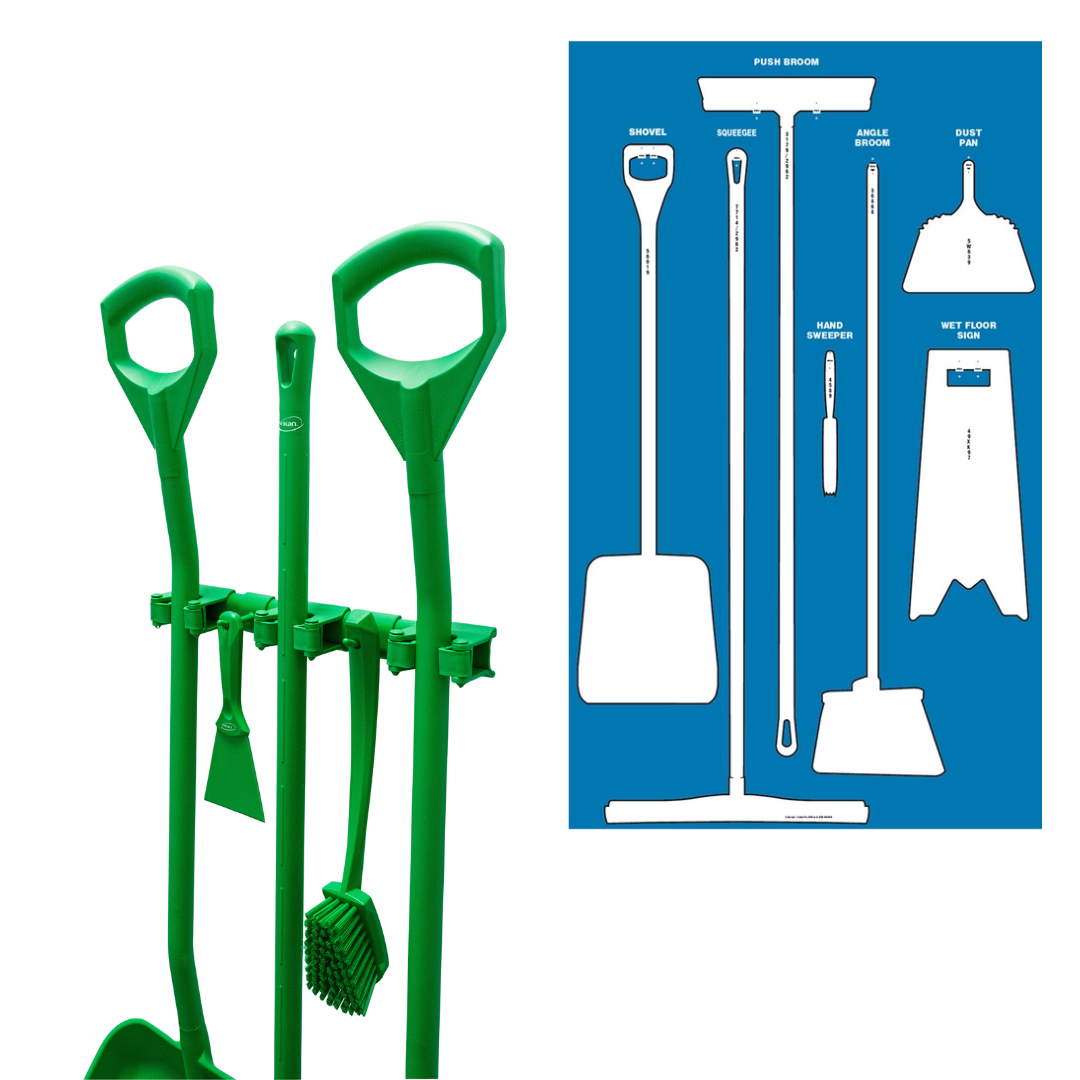

Color Coded Tools:

Scoops & Shovels

Designed for handling solid and liquid products hygienically.

Brushes & Brooms

Designed for sweeping and scrubbing. Helps clean everything from large areas to tight spaces.

Scrapers & Squeegees

Designed to push and scrape wet products.

Handles & Wall Mount

For hygienic storage and sanitation of equipment. Variety of different handles for many uses.